A Headframe or Gallows Frame is the structural frame above an underground mine shaft. Modern headframes are built out of steel, concrete or a combination of both. Timber headframes are no longer used in industrialized countries, but are still used in developing nations. Traditionally steel headframes are used when a drum hoist is employed, and concrete headframes are built for friction hoists, however a steel headframe can be used with a friction hoist for shafts with a smaller capacity and depth.

Benefits of steel headframes

A steel headframe is less expensive than a concrete headframe providing the height (defined as the vertical distance from the collar elevation to the center-line of the highest head sheave) does not exceed 50m. Steel headframes are more adaptable to modifications (making any construction errors easier to remedy), and are considerably lighter, requiring less substantial foundations. As steel headframes are easier to design, they have the potential to utilize "off the shelf" design tools. Construction of a steel headframe can be easily interrupted and restarted if necessary for statutory holidays or bad weather, where slip forming concrete is not. Upon mine closure and mine reclamation a steel headframe is easier to demolish and may have value as scrap metal.

Benefits of concrete headframes

Concrete headframes require less maintenance and are less susceptible to corrosion than steel headframes. There is much less waste of concrete during construction of a concrete headframe than there is of steel in construction of a steel headframe. Concrete headframes provide an enclosure upon construction, where steel headframes require cladding and insulation to protect from weather. Concrete headframes are less susceptible to vibrations, and sway less during high winds. Concrete is usually more readily available than steel (except in remote locations), and the price is predictable, where fabricated steel prices can be volatile.

Symbolism

Headframes have become prominent features in historic mining regions. The Ruhr district of Germany and the South Wales Valleys in Britain are both examples of areas which are now associated with headframes due to the large number constructed to mine coal during the Industrial Revolution. Most of these headframes have now been removed although both regions have turned a non-operating mines with headframes into national museums; the German Mining Museum in Bochum and Big Pit National Coal Museum in Blaenavon. Sporting teams from former coal mining regions such as Llanharan RFC and Cilfynydd RFC have headframes included in their club badges.

From http://en.wikipedia.org/

-

Ear Force X41 (XBOX LIVE Chat + Wireless Digital RF Game Audio with Dolby Headphone 7.1 Surround Sound) - Ear Force X41 (XBOX LIVE Chat + Wireless Digital RF Game Audio with Dolby Headphone 7.1 Surround Sound) by Turtle Beach [image: Ear Force X41 (XBOX LIVE C...

Tuesday, June 30, 2009

Headframe

Labels: Outline of mining

Posted by my blog at 4:41 AM 0 comments

Underground mining (hard rock)

Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, mainly those minerals containing metals such as ore containing gold, copper, zinc, nickel and lead, but also involves using the same techniques for excavating ores of gems such as diamonds. In contrast soft rock mining refers to excavation of softer minerals such as salt, coal, or oil sands.

Mine access

Underground access

Accessing underground ore can be achieved via a decline (ramp), inclined vertical shaft or adit.

* Declines can be a spiral tunnel which circles either the flank of the deposit or circles around the deposit. The decline begins with a box cut, which is the portal to the surface. Depending on the amount of overburden and quality of bedrock, a galvanized steel culvert may be required for safety purposes. They may also be started into the wall of an open cut mine.

* Shafts are vertical excavations sunk adjacent to an ore body. Shafts are sunk for ore bodies where haulage to surface via truck is not economical. Shaft haulage is more economical than truck haulage at depth, and a mine may have both a decline and a ramp.

* Adits are horizontal excavations into the side of a hill or mountain. They are used for horizontal or near-horizontal ore bodies where there is no need for a ramp or shaft.

Declines are often started from the side of the high wall of an open cut mine when the ore body is of a payable grade sufficient to support an underground mining operation but the strip ratio has become too great to support open cast extraction methods.

Ore access

Levels are excavated horizontally off the decline or shaft to access the ore body. Stopes are then excavated perpendicular (or near perpendicular) to the level into the ore.

Development mining vs. production mining

There are two principal phases of underground mining: development mining and production mining.

Development mining is composed of excavation almost entirely in (non-valuable) waste rock in order to gain access to the orebody. There are five steps in development mining: remove previously blasted material (muck out round), drill rock face, load explosives, blast explosives, and support excavation.

Production mining is further broken down into two methods, long hole and short hole. Short hole mining is similar to development mining, except that it occurs in ore. There are several different methods of long hole mining. Typically long hole mining requires two excavations within the ore at different elevations below surface, (15 m – 30 m apart). Holes are drilled between the two excavations and loaded with explosives. The holes are blasted and the ore is removed from the bottom excavation.

Ventilation

One of the most important aspects of underground hard rock mining is ventilation. Ventilation is required to clear toxic fumes from blasting and removing exhaust fumes from diesel equipment. In deep hot mines ventilation is also required for cooling the workplace for miners. Ventilation raises are excavated to provide ventilation for the workplaces, and can be modified for use as emergency escape routes. The primary sources of heat in underground hard rock mines are virgin rock temperature, machinery, auto compression, and fissure water. Other small contributing factors are human body heat and blasting.

Ground support

Some means of support is required in order to maintain the stability of the openings that are excavated. This support comes in two forms, local support and area support.

Area ground support

Area ground support is used to prevent major ground failure. Holes are drilled into the back (ceiling) and walls and a long metal bar (or rock bolt) is installed to hold the ground together. There are three categories of rock bolt, determined on the way the behave in the rock.They are:

Mechanical bolts

* Point anchor bolts (or expansion shell bolts) are a common style of area ground support. A point anchor bolt is a metal bar between 20 mm – 25 mm in diameter, and between 1 m – 4 m in length (the size is determined by the mine's engineering department). There is an expansion shell at the end of the bolt which is inserted into the hole. As the bolt is tightened by the installation drill the expansion shell expands and the bolt tightens holding the rock together. Mechanical bolts are considered temporary support as their lifespan is reduced by corrosion as they are not grouted.

Grouted bolts

* Resin grouted rebar is used in areas which require more support than a point anchor bolt can give. The rebar used is of similar size as a point anchor bolt but does not have an expansion shell. Once the hole for the rebar is drilled, cartridges of epoxy resin are installed in the hole. The rebar bolt is installed after the resin and spun by the installation drill. This opens the resin cartridge and mixes it. Once the resin hardens the drill spinning tightens the rebar bolt holding the rock together. Resin grouted rebar is considered a permanent ground support with a lifespan of 20–30 years.

* Cable bolts are used to bind large masses of rock in the hanging wall and around large excavations. Cable bolts are much larger than standard rock bolts and rebar, usually between 10–25 metres long. Cable bolts are grouted with a cement grout.

Friction bolts

* Split-sets are much easier to install than mechanical bolts or grouted bolts. The bolt is hammered into the drill hole, which has a smaller diameter than the bolt. Pressure from the bolt on the wall holds the rock together. Split-set bolts are particularly susceptible to corrosion and rust from water unless they are grouted. Once grouted the friction increases by a factor of 3-4.

* Swellex is similar to a split-set, except the bolt diameter is smaller than the hole diameter. High pressure water is injected into the bolt to expand the bolt diameter to hold the rock together. Like the split-set, swellex is poorly protected from corrosion and rust.

Local ground support

Local ground support is used to prevent smaller rocks from falling from the backs and walls. Not all excavations require local ground support.

* Welded Wire Mesh is a metal screen with 10 cm x 10 cm (4 inch) openings. It is held to the backs using point anchor bolts or resin grouted rebar.

* Shotcrete is a spray on concrete which coats the backs and walls preventing smaller rocks from falling. Shotcrete thickness can be between 50 mm – 100 mm.

* Latex Membranes can be sprayed on the backs and walls similar to shotcrete, but in smaller amounts.

Stope and retreat vs. stope and fill

Stope and retreat

Using this method, mining is planned to extract rock from the stopes without filling the voids; this allows the wall rocks to cave in to the extracted stope after all the ore has been removed. The stope is then sealed to prevent access.

Stope and fill

Where large bulk ore bodies are to be mined at great depth, or where leaving pillars of ore is uneconomical, the open stope is filled with backfill, which can be a cement and rock mixture, a cement and sand mixture or a cement and tailings mixture. This method is popular as the refilled stopes provide support for the adjacent stopes, allowing total extraction of economic resources.

Mining methods

Selective mining methods

* Cut and Fill mining is a method of short hole mining used steeply dipping or irregular ore zones, in particular where the hanging wall limits the use of long hole methods. The ore is mined in horizontal or slightly inclined slices, and filled with waste rock, sand or tailings. Either fill option may be consolidated with concrete, or left unconsolidated. Cut and fill mining is an expensive but selective method, with low ore loss and dilution.

* Drift and Fill is similar to cut and fill, except it is used in ore zones which are wider than the method of drifting will allow to be mined. In this case the first drift is developed in the ore, and is backfilled using consolidated fill. The second drift is driven adjacent to the first drift. This carries on until the ore zone is mined out to its full width, at which time the second cut is started atop of the first cut.

* Shrinkage Stoping is a short hole mining method which is suitable for steeply dipping orebodies. The method is similar to cut and fill mining with the exception that after being blasted, broken ore is left in the stope where it is used to support the surrounding rock and as a platform to work off of. Only enough ore is removed from the stope to allow for drilling and blasting the next slice. The stope is emptied when all of the ore has been blasted. Although it is very selective and allows for low dilution, since the most of the ore stays in the stope until mining is completed there is a delayed return on capital investments.

* Room and Pillar mining : Room and pillar mining is commonly done in flat or gently dipping bedded ore bodies. Pillars are left in place in a regular pattern while the rooms are mined out. In many room and pillar mines, the pillars are taken out starting at the farthest point from the stope access, allowing the roof to collapse and fill in the stope. This allows a greater recovery as less ore is left behind in pillars.

Bulk mining methods

* Block Caving is used to mine massive steeply dipping orebodies (typically low grade) with high friability. An undercut with haulage access is driven under the orebody, with "drawbells" excavated over the undercut. The drawbells serve as a place for caving rock to fall into. The orebody is drilled and blasted above the undercut, and the ore is removed via the haulage access. Due to the friability of the orebody the ore above the first blast caves and falls into the drawbells. As ore is removed from the drawbells the orebody caves in providing a steady stream of ore. If caving stops and removal of ore from the drawbells continues, a large void may form, resulting in the potential for a sudden and massive collapse and potentially catastrophic windblast throughout the mine.

Ore removal

In mines which use rubber tired equipment for coarse ore removal, the ore is removed from the stope (referred to as "mucked out" or "bogged") using center articulated vehicles (referred to as boggers or LHD ). These pieces of equipment may operate using diesel or electric engines and resemble a low-profile front end loader.

The ore is then dumped into a truck to be hauled to the surface (in shallower mines). In deeper mines the ore is dumped down an ore pass (a vertical or near vertical excavation) where it falls to a collection level. On the collection level, it may receive primary crushing via jaw or cone crusher. The ore is then moved by conveyor belts, trucks or occasionally trains to the shaft to be hoisted to the surface in buckets or skips and emptied into bins beneath the surface headframe for transport to the mill.

In some cases the underground primary crusher feeds an inclined conveyor belt which delivers ore via an incline shaft direct to the surface. The ore is fed down ore passes, with mining equipment accessing the ore body via a decline from surface.

Deepest mines

* The deepest mines in the world are the TauTona (Western Deep Levels) and Savuka gold mines in the Witwatersrand region of South Africa, which are currently working at depths exceeding 3,900 meters (about 12,800 feet ). There are plans to extend Mponeng ming, a sister mine to TauTona, down to 4,500 meters in the coming years.

* The deepest hard rock mine in North America is Xstrata's Kidd Mine, which mines copper and zinc ore in Timmins, Ontario. Mining is actively occurring 2,682 m (8,800 feet) below surface. The shaft bottoms out at over 2,926m (9,600 feet) down.

* The deepest hard rock mines in Australia are the copper and zinc lead mines in Mount Isa, Queensland at 1,800 m (5,906 feet).

* The deepest platinum-palladium mines in the world are on the Merensky Reef, in South Africa, with a resource of 203 million Troy ounces, currently worked to approximately 2,200 m (7,218 feet) depth.

* The harshest conditions for hard rock mining are in the Witwatersrand area of South Africa, where workers toil in temperatures of up to 45 °C (113 °F). However, massive refrigeration plants are used to bring the air temperature down to around 28 °C.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 4:39 AM 0 comments

Sunday, June 28, 2009

Sulfide mining

Sulfide mining a colloquial term used in Wisconsin, Michigan, and Minnesota to describe the act of mining of ore which contains significant quantities of sulfide minerals.

Copper, lead, zinc, and nickel ores are typically present in the sulfide minerals chalcopyrite, galena, sphalerite and pentlandite respectively, these minerals are often found with often appreciable amounts of pyrite.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:03 PM 0 comments

Surface mining

Surface mining is a type of mining where soil and rock overlying the mineral deposit are removed. It is the opposite of underground mining, in which the overlying rock is left in place, and the mineral removed through shafts or tunnels.

Surface mining is used when deposits of commercially useful minerals or rock are found near the surface; that is, where the overburden (surface material covering the valuable deposit) is relatively thin or the material of interest is structurally unsuitable for tunneling (as would usually be the case for sand, cinder, and gravel). Where minerals occur deep below the surface—where the overburden is thick or the mineral occurs as veins in hard rock— underground mining methods are used to extract the valued material. Surface mines are typically enlarged until either the mineral deposit is exhausted, or the cost of removing larger volumes of overburden makes further mining uneconomic.

In most forms of surface mining, heavy equipment, such as earthmovers, first remove the overburden - the soil and rock above the deposit. Next, huge machines, such as dragline excavators, extract the mineral.

Types of surface mining

There are five main forms of surface mining, detailed below.

Strip mining

"Strip mining" is the practice of mining a seam of mineral by first removing a long strip of overlying soil and rock (the overburden). It is most commonly used to mine coal or tar sand. Strip mining is only practical when the ore body to be excavated is relatively near the surface. This type of mining uses some of the largest machines on earth, including bucket-wheel excavators which can move as much as 12,000 cubic meters of earth per hour.

There are two forms of strip mining. The more common method is "area stripping", which is used on fairly flat terrain, to extract deposits over a large area. As each long strip is excavated, the overburden is placed in the excavation produced by the previous strip.

"Contour stripping" involves removing the overburden above the mineral seam near the outcrop in hilly terrain, where the mineral outcrop usually follows the contour of the land. Contour stripping is often followed by auger mining into the hillside, to remove more of the mineral. This method commonly leaves behind terraces in mountainsides.

Among others, strip mining is used to extract the oil-impregnated sand in the Athabasca Tar Sands in Alberta. It is also common in coal mining. Bucket-wheel excavators are widely used for this purpose, however, they are prone to damage and require many millions of dollars to repair.

Open-pit mining

"Open-pit mining" refers to a method of extracting rock or minerals from the earth from their removal from an open pit or borrow. Although open-pit mining is sometimes mistakenly referred to as "strip mining", the two methods are different (see above).

Mountaintop removal

"Mountaintop removal mining" (MTR) is a destructive form of coal mining that uses three million pounds of explosives per day to blast 600 to 800 feet (240 m) off the top of densely forested Appalachian mountains. The mining waste or "overburden" is dumped by large trucks into mountain streams. MTR involves the mass restructuring of earth in order to reach the coal seam as deep as 1,000 feet (300 m) below the surface. It is used where a coal seam outcrops all the way around a mountain top. All the rock, soil, trees and vegetation above the coal seam are removed and dumped in adjacent lows such as hollows or ravines. Mountaintop removal replaces previously steep forested topography with a monocultural grassland on a relatively level surface. Economic development attempts on reclaimed mine sites include prisons such the Big Sandy Federal Penitentiary in Martin County, Kentucky, small town airports, golf courses such as Twisted Gun in Mingo County, West Virginia and Stonecrest Golf Course in Floyd County, Kentucky, as well as industrial scrubber sludge disposal sites, solid waste landfills, trailer parks, explosive manufacturers, and storage rental lockers.

The technique has been used increasingly in recent years in the Appalachian coal fields of West Virginia, Kentucky, Virginia and Tennessee in the United States. The profound changes in topography and disturbance of pre-existing ecosystems have made mountaintop removal highly controversial.

Advocates of mountaintop removal point out that once the areas are reclaimed as mandated by law, the technique provides premium flat land suitable for many uses in a region where flat land is at a premium. They also maintain that the new growth on reclaimed mountaintop mined areas is better able to support populations of game animals.

Critics contend that mountaintop removal is a disastrous practice that benefits a small number of corporations at the expense of local communities and the environment. A U.S. Environmental Protection Agency (EPA) environmental impact statement finds that streams near valley fills from mountaintop removal contain high levels of minerals in the water and decreased aquatic biodiversity. The statement also estimates that 724 miles (1,165 km) of Appalachian streams were buried by valley fills from 1985 to 2001.

In common with other methods of coal mining, processing the coal mined by mountaintop removal generates waste slurry (also called "coal sludge"), which is usually stored behind a dam on-site. Many coal slurry impoundments in West Virginia exceed 500 million gallons in volume, and some, including the Brushy Fork impoundment in Raleigh County, exceed 7 billion gallons. Such impoundments can be hundreds of feet high and be in close proximity to schools or private residences.The most controversial sludge dam at present sits 400 yards (370 m) above Marsh Fork Elementary School. The sludge pond is permitted to hold 2.8 billion gallons of toxic sludge, and is 21 times larger than the pond which killed 125 people in the Buffalo Creek Flood.

Blasting at a mountaintop removal mine expels coal dust and fly-rock into the air, which can then disturb or settle onto private property nearby. This dust contains sulfur compounds, which corrode structures and tombstones and is a health hazard.

Although MTR sites are usually reclaimed after mining is complete, reclamation has traditionally focused on stabilizing rock and controlling erosion, but not reforesting the area with trees.Quick-growing, non-native grasses, planted to quickly provide vegetation on a site, compete with tree seedlings, and trees have difficulty establishing root systems in compacted backfill. Consequently, biodiversity suffers in a region of the United States with numerous endemic species. Erosion also increases, which can intensify flooding. In the Eastern United States, the Appalachian Regional Reforestation Initiative works to promote the use of trees in mining reclamation.

Dredging

"Dredging" is a method often used to bring up underwater mineral deposits. Although dredging is usually employed to clear or enlarge waterways for boats, it can also recover significant amounts of underwater minerals relatively efficiently and cheaply.

Highwall mining

Highwall mining is another form of surface mining that evolved from auger mining. In highwall mining, the coal seam is penetrated by a continuous miner propelled by a hydraulic Pushbeam Transfer Mechanism (PTM). A typical cycle includes sumping (pushing forward) and shearing (raising or lowering the cutterhead boom to cut the entire height of the coal seam). As the coal recovery cycle continues, the cutterhead is progressively pushed into the coal seam for 20 feet (6.1 m). Then, the Pushbeam Transfer Mechanism (PTM) automatically inserts a 20-foot (6.1 m) long rectangular pushbeam into the center section of the machine between the powerhead and the cutterhead. The pushbeams system can penetrate nearly 1,000 feet (300 m) into the coal seam. Some highwall mining systems use augers enclosed inside the pushbeams that prevent the mined coal from being contaminated by rock debris during the conveyance process. Using a video imaging and/or a gamma detector, the operator can see and guide the continuous miner's progress. Highwall mining can produce thousands of tons of clean coal in contour-strip operations with narrow benches, previously mined areas, or trench mine applications.

Recovery is much better than augering, but the mapping of areas that have been developed by a highwall miner are not mapped as rigorously as deep mined areas. Very little spoil is displaced in contrast with mountain top removal, however a large amount of capital is required to operate and own a highwall miner.

Mapping of the outcrop as well as core hole data and samples taken during the bench making process are taken into account to best project the panels that the highwall miner will cut. Obstacles that could be potentially damaged by subsidence and the natural contour of the Highwall are taken into account, and a surveyor points the Highwall miner in a line mostly perpendicular to the highwall. Parallel lines represent the panels cut into the mountain (up to 1,000 feet (300 m) deep), because changing the azimuth during mining results in missing a portion of the coal seam. Recently highwall miners have penetrated more than 1050 feet into the coal seam, and today's models are capable of going farther, limited only by the amount of cable on the machine. The maximum depth would be determined by the stress of further penetration and associated power draw.

Environmental and health issues

The large impact of surface mining on the topography, vegetation, and water resources has made it highly controversial.

Surface mining is subject to state and federal reclamation requirements, but adequacy of the requirements is a constant source of contention. Unless reclaimed, surface mining can leave behind large areas of infertile waste rock, as 70% of material excavated is waste.

In the United States, the Surface Mining Control and Reclamation Act of 1977 mandates reclamation of surface coal mines. Reclamation for non-coal mines is regulated by state and local laws, which may vary widely.

Human health

The United Mine Workers of America has spoken against the use of human sewage sludge to reclaim surface mining sites in Appalachia. The UMWA launched its campaign against the use of sludge on mine sites in 1999 after eight UMWA workers became ill from exposure to Class B sludge spread near their workplace.

On August 20, 2004 at 2:30 a.m. a boulder accidentally pushed off an A&G Coal surface mine above the town of Inman, Virginia rolled 649 feet (198 m) down the mountain and into a home. Three-year-old Jeremy Davidson was crushed in his bed while he slept. The Davidson family settled with A&G Coal for $3 million in 2006, and left the region.

Flooding exacerbated by logging operations and coal surface mining, especially mountaintop removal mines has caused damage in Appalachian communities including the communities of Dorothy, Welch, Keystone, Oceana, Davey, Belo and Delbarton, West Virginia. Flash flooding on July 8, 2001 and May 2, 2002 killed eight West Virginians and washed away homes throughout southern West Virginia. Mountaintop removal mining removes all vegetation, and these trees normally absorb up to 75 percent of rainfall in a mature healthy forest, according to the Federal Office of Surface Mining.

The Martin County Sludge Spill was an accident that occurred after midnight on October 11, 2000 when the bottom of a coal sludge impoundment at a surface mine owned by Massey Energy in Martin County, Kentucky, broke into an abandoned underground mine below. The slurry came out of the mine openings, sending an estimated 306 million gallons (1.16 billion liters) of sludge down two tributaries of the Tug Fork River. By morning, Wolf Creek was oozing with the black waste; on Coldwater Fork, a ten-foot (3 m) wide stream became a 100-yard (91 m) expanse of thick sludge. The spill was over five feet deep in places and covered nearby residents' yards. The spill polluted hundreds of miles (300 - 500 km) of the Big Sandy River and its tributaries and the Ohio River. The water supply for over 27,000 residents was contaminated, and all aquatic life in Coldwater Fork and Wolf Creek was killed. The spill was 30 times larger than the Exxon Valdez oil spill (12 million gallons) and one of the worst environmental disasters ever in the southeastern United States, according to the United States Environmental Protection Agency.

Surface mining creates problems for the human health: gases, dust in suspension, noises and vibrations from the machines and explosions, that can create lung or nervous diseases

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:02 PM 0 comments

Saturday, June 27, 2009

Stoping (mining method)

Stoping is the removal of the wanted ore from an underground mine leaving behind an open space known as a stope. Stoping is used when the country rock is sufficiently strong not to cave into the stope, although in most cases artificial support is also provided. As mining progresses the stope is often backfilled with tailings, or when needed for strength, a mixture of this material and cement.

In the past stoping took place with manual tools or by fire-setting; later gunpowder was used, and from the 19th century various other explosives and power-tools came into use.

In old mines, stopes frequently collapse at a later time, leaving craters at the surface. They are an unexpected danger when all records of underground mining have been lost due to the passage of time.

Types of stoping

A stope can be created in a variety of ways, depending on the geology of the ore body being mined. It is common to dig shafts vertically downwards to reach the ore body and then drive horizontal levels through it. Stoping then takes place from these levels, in its simplest form as overhand and underhand stoping, which refer to the removal of ore from above or below the level, respectively. In steeply-dipping ore bodies, such as lodes of tin, the stopes become long narrow near-vertical spaces, which, if one reaches the surface is known as a gunnis or coffen. A common method of mining such vertical ore bodies is stull stoping, see below.

When the ore body is more or less horizontal, various forms of room and pillar stoping, cut and fill, or longwall mining can take place.

Stull stoping

Stull stoping is a form of stoping used in hardrock mining that uses systematic or random timbering ("stulls") placed between the foot and hanging wall of the vein. The method requires that the hanging wall and often the footwall be of competent rock as the stulls provide the only artificial support. This type of stope has been used up to a depth of 3,500 feet (1,077 m) and at intervals up to 12 feet (3.7 m) wide. The 1893 mining disaster at Dolcoath mine in Cornwall was caused by failure of the stulls holding up a huge weight of waste rock.

Shrinkage stoping

Shrinkage stope mining, or shrinkage stoping, is most suitable for steeply dipping ore bodies (70°—90°). In shrinkage stoping, mining proceeds from the bottom upwards, in horizontal slices (similar to cut and fill mining), with the broken ore being left in place for miners to work off. Because blasted rock takes up a greater volume than in situ rock (due to swell factor), some of the blasted ore (approximately 40%) must be removed to provide working space for the next ore slice. Once the top of the stope is reached all the ore is removed from the stope. The stope may be backfilled or left empty depending on the rock conditions.

Long hole stoping

Long hole stoping can be the lowest cost method when large ore bodies are located in strong country rock. In operation it is similar to an underground version of quarrying.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 8:11 PM 0 comments

Slope mining

Slope mining is a method of accessing valuable geological material, such as coal. A sloping access shaft travels downwards towards the coal seam. Slope mines differ from shaft and drift mines, which access resources by tunneling straight down or horizontally, respectively.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 8:08 PM 0 comments

Wednesday, June 24, 2009

Shaft mining

Shaft mining or Shaft sinking refers to the method of excavating a vertical or near-vertical tunnel from the top down, where there is initially no access to the bottom. When the top of the excavation is the ground surface, it is referred to as a shaft, when the top of the excavation is underground, it is called a winze.

Off-shaft access

The mine shaft is used to access to an underground mining facility. Horizontal workings off the shaft are called drifts, galleries or levels. These extend from the central shaft towards the ore body. The point of contact between these levels and the shaft itself is known as the inset, shaft station or plat.

Surface facilities

On the surface above the shaft stands a building known as the headframe (or winding tower, poppet head or pit head). Depending on the type of hoist used the top of the headframe will either house a hoist motor or a sheave wheel (with the hoist motor mounted on the ground). The headframe will also contain bins for storing ore being transferred to the processing facility. If the shaft is used for mine ventilaton a plenum or casing, is incorporated into the headframe to ensure the proper flow of air into and out of the mine.

Shaft lining

In North and South America, smaller shafts are designed to be rectangular with timber supports. Larger shafts are round and are concrete lined.

Shaft compartments

A mine shaft is frequently split into multiple compartments. The largest compartment is typically used for the cage, a conveyance used for moving workers and supplies below the surface. It functions in a similar manner to an elevator. The second compartment is used for one or more skips, used to hoist ore to the surface. Smaller mining operations use a skip mounted underneath the cage, rather than a separate device, while some large mines have separate shafts for the cage and skips. The third compartment is used for an emergency exit; it may house an auxiliary cage or a system of ladders. An additional compartment houses mine services such as high voltage cables and pipes for transfer of water, compressed air or diesel fuel.

A second reason to divide the shaft is for ventilation. One or more of the compartments discussed above may be used for air intake, while others may be used for exhaust.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 4:21 PM 0 comments

Thursday, June 18, 2009

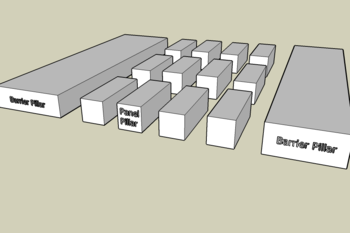

Room and pillar

Room and pillar (also called bord and pillar) is a mining system in which the mined material is extracted across a horizontal plane while leaving "pillars" of untouched material to support the overburden leaving open areas or "rooms" underground. It is usually used for relatively flat-lying deposits, such as those that follow a particular stratum.

The room and pillar system is used in mining coal, iron and base metals ores particularly when found as manto or blanket deposits, stone and aggregates, talc, soda ash and potash.

The key to the successful room and pillar mining is selecting the optimum pillar size. If the pillars are too small the mine will collapse. If the pillars are too large then significant quantities of valuable material will be left behind reducing the profitability of the mine. The percentage of material mined varies depending on many factors, including the material mined, height of the pillar, and roof conditions; typical values are: stone and aggregates 75%, coal 60%, and potash 50%.

Mine Layout

Room and Pillar mines are developed on a grid basis except where geological features such as faults require the regular pattern to be modified. The size of the pillars is determined by calculation. The load bearing capacity of the material above and below the material being mined and the capacity of the mined material itself will determine the pillar size.

If one pillar fails and surrounding pillars are unable to support the area previously supported by the failed pillar they may in turn fail. This could lead to the collapse of the whole mine. To prevent this the mine is divided up into areas or panels. Pillars known as barrier pillars separate the panels. The barrier pillars are significantly larger than the "panel" pillars and are sized to allow them to support a significant part of the panel and prevent progressive collapse of the mine in the event failure of the panel pillars.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:26 PM 0 comments

Retreat mining

Retreat mining is a term used to reference the final phase of an underground mining technique known as room and pillar mining. This involves excavating a room or chamber while leaving behind pillars of material for support. This excavation is carried out in a pattern advancing away from the entrance of a mine. Once a deposit has been exhausted using this method, the pillars that were left behind initially are removed, or 'pulled', retreating back towards the mine's entrance. After the pillars are removed, the roof (or back) is allowed to collapse behind the mining area. Pillar removal must occur in a very precise order in order to reduce the risks to workers, due to the high stresses placed on the remaining pillars by the abutment stresses of the caving ground.

Retreat mining is the term commonly referred to as the mining method employed by the Crandall Canyon Mine and is believed, by some, to be a factor in the August 2007 collapse which trapped six miners. On November 21, 2007, the mine was sealed, entombing the deceased miners. The bureau of land management says retreat mining was being used. Robert E. Murray, CEO of Murray Energy (owner of the mine) says the technique was not being used at Crandall Canyon.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:25 PM 0 comments

Wednesday, May 27, 2009

Ore genesis

he various theories of ore genesis explain how the various types of mineral deposits form within the Earth's crust. Ore genesis theories are very dependent on the mineral or commodity.

Ore genesis theories generally involve three components: source, transport or conduit, and trap. This also applies to the petroleum industry, which was first to use this methodology.

* Source is required because metal must come from somewhere, and be liberated by some process

* Transport is required first to move the metal bearing fluids or solid minerals into the right position, and refers to the act of physically moving the metal, as well as chemical or physical phenomenon which encourage movement

* Trapping is required to concentrate the metal via some physical, chemical or geological mechanism into a concentration which forms mineable ore

The biggest deposits are formed when the source is large, the transport mechanism is efficient, and the trap is active and ready at the right time.

Ore genesis processes

Evans (1993) divides ore genesis into the following main categories based on physical process. These are internal processes, hydrothermal processes, metamorphic processes and surficial processes.

Internal processes

These processes are integral physical phenomena and chemical reactions internal to magmas, generally in plutonic or volcanic rocks. These include;

* Fractional crystallization, either creating monominerallic cumulate ores or contributing to the enrichment of ore minerals and metals

* Liquation, or liquid immiscibility between melts of differing composition, usually sulfide segregations of nickel-copper-platinoid sulfides and silicates.

Hydrothermal processes

These processes are the physico-chemical phenomena and reactions caused by movement of hydrothermal waters within the crust, often as a consequence of magmatic intrusion or tectonic upheavals. The foundations of hydrothermal processes are the source-transport-trap mechanism.

Sources of hydrothermal solutions include seawater, formational brines (water trapped within sediments at deposition) and metamorphic fluids created by dehydration of hydrous minerals during metamorphism.

Metal sources may include a plethora of rocks. However most metals of economic importance are carried as trace elements within rock-forming minerals, and so may be liberated by hydrothermal processes. This happens because of

* incompatibility of the metal with its host mineral, for example zinc in calcite, which favours aqueous fluids in contact with the host mineral under diagenesis.

* solubility of the host mineral within nascent hydrothermal solutions in the source rocks, for example mineral salts (halite), carbonates (cerussite), phosphates (monazite and thorianite) and sulfates (barite)

* elevated temperatures causing decomposition reactions of minerals

Transport by hydrothermal solutions usually requires a salt or other soluble species which can form a metal-bearing complex. These metal-bearing complexes facilitate transport of metals within aqueous solutions, generally as hydroxides, but also by processes similar to chelation.

This process is especially well understood in gold metallogeny where various thiosulfate, chloride and other gold-carrying chemical complexes (notably tellurium-chloride/sulfate or antimony-chloride/sulfate). The majority of metal deposits formed by hydrothermal processes include sulfide minerals, indicating sulfur is an important metal-carrying complex.

Sulfide deposition:

Sulfide deposition within the trap zone occurs when metal-carrying sulfate, sulfide or other complexes become chemically unstable due to one or more of the following processes;

* falling temperature, which renders the complex unstable or metal insoluble

* loss of pressure, which has the same effect

* reaction with chemically reactive wall rocks, usually of reduced oxidation state, such as iron bearing rocks, mafic or ultramafic rocks or carbonate rocks

* degassing of the hydrothermal fluid into a gas and water system, or boiling, which alters the metal carrying capacity of the solution and even destroys metal-carrying chemical complexes

Metal can also become precipitated when temperature and pressure or oxidation state favour different ionic complexes in the water, for instance the change from sulfide to sulfate, oxygen fugacity, exchange of metals between sulfide and chloride complexes, et cetera.

Metamorphic processes

Lateral secretion:

Ore deposits formed by lateral secretion are formed by metamorphic reactions during shearing, which liberate mineral constituents such as quartz, sulfides, gold, carbonates and oxides from deforming rocks and focus these constituents into zones of reduced pressure or dilation such as faults. This may occur without much hydrothermal fluid flow, and this is typical of podiform chromite deposits.

Metamorphic processes also control many physical processes which form the source of hydrothermal fluids, outlined above.

Surficial processes

Surficial processes are the physical and chemical phenomena which cause concentration of ore material within the regolith, generally by the action of the environment. This includes placer deposits, laterite deposits and residual or eluvial deposits. The physical processes of ore deposit formation in the surficial realm include;

* erosion

* deposition by sedimentary processes, including winnowing, density separation (eg; gold placers)

* weathering via oxidation or chemical attack of a rock, either liberating rock fragments or creating chemically deposited clays, laterites or manto ore deposits

* Deposition in low-energy environments in beach environments

Classification of ore deposits

Ore deposits are usually classified by ore formation processes and geological setting. For example, SEDEX deposits, literally meaning "sedimentary exhalative" are a class of ore deposit formed on the sea floor (sedimentary) by exhalation of brines into seawater (exhalative), causing chemical precipitation of ore minerals when the brine cools, mixes with sea water and loses its metal carrying capacity.

Ore deposits rarely fit snugly into the boxes in which geologists wish to place them. Many may be formed by one or more of the basic genesis processes above, creating ambiguous classifications and much argument and conjecture. Often ore deposits are classified after examples of their type, for instance Broken Hill Type lead-zinc-silver deposits or Carlin-type Gold deposits.

Classification of hydrothermal ore deposits is also achieved by classifying according to the temperature of formation, which roughly also correlates with particular mineralising fluids, mineral associations and structural styles. This scheme, proposed by Waldemar Lindgren (1933) classified hydrothermal deposits as hypothermal, mesothermal, epithermal and telethermal.

Genesis of common ores

This page has been organised by metal commodity; it is also possible to organise theories according to geological criteria of formation, as well as by metal association. Often ores of the same metal can be formed by multiple processes, and this is described by commodity.

Iron

Iron ores are overwhelmingly derived from ancient sediments known as banded iron formations (BIFs). These sediments are composed of iron oxide minerals deposited on the sea floor. Particular environmental conditions are needed to transport enough iron in sea water to form these deposits, such as acidic and oxygen-poor atmospheres within the Proterozoic Era.

Often, more recent weathering during the Tertiary or Eocene is required to convert the usual magnetite minerals into more easily processed hematite. Some iron deposits within the Pilbara of West Australia are placer deposits, formed by accumulation of hematite gravels called pisolites which form channel-iron deposits. These are preferred because they are cheap to mine.

Lead zinc silver

Lead-zinc deposits are generally accompanied by silver, hosted within the lead sulfide mineral galena or within the zinc sulfide mineral sphalerite.

Lead and zinc deposits are formed by discharge of deep sedimentary brine onto the sea floor (termed sedimentary exhalative or SEDEX), or by replacement of limestone, in skarn deposits, some associated with submarine volcanoes (called volcanogenic massive sulfide ore deposits or VMS) or in the aureole of subvolcanic intrusions of granite. The vast majority of SEDEX lead and zinc deposits are Proterozoic in age, although there are significant Jurassic examples in Canada and Alaska.

The carbonate replacement type deposit is exemplified by the Mississippi valley type (MVT) ore deposits. MVT and similar styles occur by replacement and degradation of carbonate sequences by hydrocarbons, which are thought important for transporting lead.

Gold

Gold deposits are formed via a very wide variety of geological processes. Deposits are classified as primary, alluvial or placer deposits, or residual or laterite deposits. Often a deposit will contain a mixture of all three types of ore.

Plate tectonics is the underlying mechanism for generating gold deposits. The majority of primary gold deposits fall into two main categories: lode gold deposits or intrusion-related deposits.

Lode gold deposits are generally high-grade, thin, vein and fault hosted. They are comprised primarily of quartz veins also known as lodes or reefs, which contain either native gold or gold sulfides and tellurides. Lode gold deposits are usually hosted in basalt or in sediments known as turbidite, although when in faults, they may occupy intrusive igneous rocks such as granite.

Lode-gold deposits are intimately associated with orogeny and other plate collision events within geologic history. Most lode gold deposits sourced from metamorphic rocks because it is thought that the majority are formed by dehydration of basalt during metamorphism. The gold is transported up faults by hydrothermal waters and deposited when the water cools too much to retain gold in solution.

Intrusive related gold (Lang & Baker, 2001) is generally hosted in granites, porphyry or rarely dikes. Intrusive related gold usually also contains copper, and is often associated with tin and tungsten, and rarely molybdenum, antimony and uranium. Intrusive-related gold deposits rely on gold existing in the fluids associated with the magma (White, 2001), and the inevitable discharge of these hydrothermal fluids into the wall-rocks (Lowenstern, 2001). Skarn deposits are another manifestation of intrusive-related deposits.

Placer deposits are sourced from pre-existing gold deposits and are secondary deposits. Placer deposits are formed by alluvial processes within rivers, streams and on beaches. Placer gold deposits form via gravity, with the density of gold causing it to sink into trap sites within the river bed, or where water velocity drops, such as bends in rivers and behind boulders. Often placer deposits are found within sedimentary rocks and can be billions of years old, for instance the Witwatersrand deposits in South Africa. Sedimentary placer deposits are known as 'leads' or 'deep leads'.

Placer deposits are often worked by fossicking, and panning for gold is a popular pastime.

Laterite gold deposits are formed from pre-existing gold deposits (including some placer deposits) during prolonged weathering of the bedrock. Gold is deposited within iron oxides in the weathered rock or regolith, and may be further enriched by reworking by erosion. Some laterite deposits are formed by wind erosion of the bedrock leaving a residuum of native gold metal at surface.

Platinum

Platinum and palladium are precious metals generally found in ultramafic rocks. The source of platinum and palladium deposits is ultramafic rocks which have enough sulfur to form a sulfide mineral while the magma is still liquid. This sulfide mineral (usually pentlandite, pyrite, chalcopyrite or pyrrhotite) gains platinum by mixing with the bulk of the magma because platinum is chalcophile and is concentrated in sulfides. Alternatively, platinum occurs in association with chromite either within the chromite mineral itself or within sulfides associated with it.

Sulfide phases only form in ultramafic magmas when the magma reaches sulfur saturation. This is generally thought to be nearly impossible by pure fractional crystallisation, so other processes are usually required in ore genesis models to explain sulfur saturation. These include contamination of the magma with crustal material, especially sulfur-rich wall-rocks or sediments; magma mixing; volatile gain or loss.

Often platinum is associated with nickel, copper, chromium, and cobalt deposits.

Nickel

Nickel deposits are generally found in two forms, either as sulfide or laterite.

Sulfide type nickel deposits are formed in essentially the same manner as platinum deposits. Nickel is a chalcophile element which prefers sulfides, so an ultramafic or mafic rock which has a sulfide phase in the magma may form nickel sulfides. The best nickel deposits are formed where sulfide accumulates in the base of lava tubes or volcanic flows — especially komatiite lavas.

Komatiitic nickel-copper sulfide deposits are considered to be formed by a mixture of sulfide segregation, immiscibility, and thermal erosion of sulfidic sediments. The sediments are considered to be necessary to promote sulfur saturation.

Some subvolcanic sills in the Thompson Belt of Canada host nickel sulfide deposits formed by deposition of sulfides near the feeder vent. Sulfide was accumulated near the vent due to the loss of magma velocity at the vent interface. The massive Voisey's Bay nickel deposit is considered to have formed via a similar process.

The process of forming nickel laterite deposits is essentially similar to the formation of gold laterite deposits, except that ultramafic or mafic rocks are required. Generally nickel laterites require very large olivine-bearing ultramafic intrusions. Minerals formed in laterite nickel deposits include gibbsite.

Copper

Copper is found in association with many other metals and deposit styles. Commonly, copper is either formed within sedimentary rocks, or associated with igneous rocks.

The world's major copper deposits are formed within the granitic porphyry copper style. Copper is enriched by processes during crystallisation of the granite and forms as chalcopyrite — a sulfide mineral, which is carried up with the granite.

Sometimes granites erupt to surface as volcanoes, and copper mineralisation forms during this phase when the granite and volcanic rocks cool via hydrothermal circulation.

Sedimentary copper forms within ocean basins in sedimentary rocks. Generally this forms by brine from deeply buried sediments discharging into the deep sea, and precipitating copper and often lead and zinc sulfides directly onto the sea floor. This is then buried by further sediment. This is a process similar to SEDEX zinc and lead, although some carbonate-hosted examples exist.

Often copper is associated with gold, lead, zinc and nickel deposits.

Uranium

Uranium deposits are usually sourced from radioactive granites, where certain minerals such as monazite are leached during hydrothermal activity or during circulation of groundwater. The uranium is brought into solution by acidic conditions and is deposited when this acidity is neutralised. Generally this occurs in certain carbon-bearing sediments, within an unconformity in sedimentary strata. The majority of the world's nuclear power is sourced from uranium in such deposits.

Uranium is also found in nearly all coal at several parts per million, and in all granites. Radon is a common problem during mining of uranium as it is a radioactive gas.

Uranium is also found associated with certain igenous rocks, such as granite and porphyry. The Olympic Dam deposit in Australia is an example of this type of uranium deposit. It contains 70% of Australia's share of 40% of the known global low-cost recoverable uranium inventory.

Titanium and zirconium

Mineral sands are the predominant type of titanium, zirconium and thorium deposit. They are formed by accumulation of such heavy minerals within beach systems, and are a type of placer deposits. The minerals which contain titanium are ilmenite, rutile and leucoxene, zirconium is contained within zircon, and thorium is generally contained within monazite. These minerals are sourced from primarily granite bedrock by erosion and transported to the sea by rivers where they accumulate within beach sands. Rarely, but importantly, gold, tin and platinum deposits can form in beach placer deposits.

Tin, tungsten, and molybdenum

These three metals generally form in a certain type of granite, via a similar mechanism to intrusive-related gold and copper. They are considered together because the process of forming these deposits is essentially the same. Skarn type mineralisation related to these granites is a very important type of tin, tungsten and molybdenum deposit. Skarn deposits form by reaction of mineralised fluids from the granite reacting with wall rocks such as limestone. Skarn mineralisation is also important in lead, zinc, copper, gold and occasionally uranium mineralisation.

Greisen granite is another related tin-molybdenum and topaz mineralisation style.

Rare earth elements, niobium, tantalum, lithium

The overwhelming majority of rare earth elements, tantalum and lithium are found within pegmatite. Ore genesis theories for these ores are wide and varied, but most involve metamorphism and igneous activity. Lithium is present as spodumene or lepidolite within pegmatite.

Carbonatite intrusions are an important source of these elements. Ore minerals are essentially part of the unusual mineralogy of carbonatite.

Phosphate

Phosphate is used in fertilisers. Immense quantities of phosphate rock or phosphorite occur in sedimentary shelf deposits, ranging in age from the Proterozoic to currently forming environments. Phosphate deposits are thought to be sourced from the skeletons of dead sea creatures which accumulated on the seafloor. Similar to iron ore deposits and oil, particular conditions in the ocean and environment are thought to have contributed to these deposits within the geological past.

Phosphate deposits are also formed from alkaline igneous rocks such as nepheline syenites, carbonatites and associated rock types. The phosphate is, in this case, contained within magmatic apatite, monazite or other rare-earth phosphates.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 7:01 AM 0 comments

Ore dressing

Ore dressing is one of the principal processes in the work of mining. It consists of separating economically valuable minerals from those with little or no value, or of separating valuable minerals from each other, so that they may be further processed, for example by smelting.

Purpose

When minerals are brought up from the mine to the surface, they commonly contain a variety of materials. The contained metal may be either in the native uncombined state or a chemical compound (commonly sulfides or oxides of metals), but in either case the valuable mineral ore is always associated with minerals of little or no value (gangue). The province of the ore-dresser is to separate the valuables from the waste, for example, quartz, feldspar, or calcite, by mechanical means, obtaining thereby concentrates and tailings. It is then the province of the metallurgist to extract the pure metal from the concentrates by chemical means, with or without the aid of heat.

There are also a number of non-metallic minerals which do not have any value, or at best do not reach their highest value until they have been subjected to some form of mechanical preparation; among them are diamonds, graphite, corundum, garnet, asbestos, and coal.

Methods

Ore commonly has to be crushed, so that crystals of different minerals adhering to each other are broken apart. These then have to be separated. The crushing process is known as "spalling".

Crushing

Traditionally, the raw mineral was broken up using hammers, wielded by hand. Later mechanical means were found to achieve this. An early example of this was the Cornish stamp, consisting of a series of iron hammers mounted in a vertical frame, raised by cams on the shaft of a waterwheel and falling on to the ore under gravity. These have been replaced by other machinery.

Separation

The simplest method of separating ore from gangue consists of the picking out the individual crystals of each. However this is a very tedious process, particularly when the individual particles are small.

Another comparatively simple method relies on the various minerals having different densities, causing them to collect in different places: metallic minerals (being heavier) will drop out of suspension more quickly than lighter ones, which will be carried further by a stream of water (or other liquid). One variety of apparatus for this is the 'buddle'.

Alternatively, if a fluid of a suitable density can be provided, lighter minerals will float and heavier ones sink. This is known as floatation.

Glossary of ore dressing terms

Some of these definitions are from Chambers Twentieth Century Dictionary:

* Buddle,

o (noun), an inclined hutch or circular frame of various types, used for washing ore

o (verb), to wash with a buddle

* Frue Vanner, a ore-dressing machine using an inclined rubber belt

* Hutch (noun), a trough used with some ore-dressing machines

* Keeve or kieve (noun), a large tub

* Spale (noun), a splinter or chip (Scottish)

* Spall,

o (noun), a chip or splinter, especially of stone

o (verb), to split, splinter or chip

* Vanning, a simple method of assessing the ore content of a sample

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:59 AM 0 comments

Ore

An ore is a type of rock that contains minerals such as gemstones and metals that can be extracted through mining and refined for use. Samples of ore in the form of exceptionally beautiful crystals, exotic layering visible when sectioned or polished or metallic presentations such as large nuggets or crystalline formations of metals such as gold or copper may command a value far beyond their value as mere ore or raw metal for subsequent reduction to utilitarian purposes.

The grade or concentration of an ore mineral, or metal, as well as its form of occurrence, will directly affect the costs associated with mining the ore. The cost of extraction must thus be weighted against the contained metal value of the rock to determine what ore can be profitably extracted and what ore is of too low a grade to be worth mining. Metal ores are generally oxides, sulfides, silicates, or "native" metals (such as native copper) that are not commonly concentrated in the Earth's crust or "noble" metals (not usually forming compounds) such as gold. The ores must be processed to extract the metals of interest from the waste rock and from the ore minerals. Ore bodies are formed by a variety of geological processes. The process of ore formation is called ore genesis.

Ore deposits

An ore deposit is an accumulation of ore. This is distinct from a mineral resource as defined by the mineral resource classification criteria. An ore deposit is one occurrence of the particular ore type. Most ore deposits are named according to either their location (for example the Witswatersrand, South Africa), or after a discoverer (eg; the kambalda nickel shoots are named after drillers), or after some whimsy, an historical figure, a prominent person, something from mythology (phoenix, kraken, etc) or the code name of the resource company which found it (eg; MKD-5 is the in-house name for the Mount Keith nickel

Classification of ore deposits

Ore deposits are classified according to various criteria developed via the study of economic geology, or ore genesis. The classifications below are typical

Hydrothermal epigenetic deposits

* Mesothermal lode gold deposits, typified by the Golden Mile, Kalgoorlie

* Archaean conglomerate hosted gold-uranium deposits, typified by Elliot Lake, Canada and Witwatersrand, South Africa

* Carlin type gold deposits, including;

o Dolomite-hosted jasperoid replacement subtype

* Epithermal stockwork vein deposits

wddeWEF

Granite related hydrothermal

* IOCG or iron oxide copper gold deposits, typified by the supergiant Olympic Dam Cu-Au-U deposit

* Porphyry copper +/- gold +/- molybdenum +/- silver deposits

* Intrusive-related copper-gold +/- (tin-tungsten), typified by the Tombstone, Arizona deposits

* Hydromagmatic magnetite iron ore deposits and skarns

* Skarn ore deposits of copper, lead, zinc, tungsten, etcetera

Nickel-cobalt-platinum deposits

* Magmatic nickel-copper-iron-PGE deposits including

o Cumulate vanadiferous or platinum-bearing magnetite or chromite

o Cumulate hard-rock titanium (ilmenite) deposits

o Komatiite hosted Ni-Cu-PGE deposits

o Subvolcanic feeder subtype, typified by Noril'sk-Talnakh and the Thompson Belt, Canada

o Intrusive-related Ni-Cu-PGE, typified by Voisey's Bay, Canada and Jinchuan, China

* Lateritic nickel ore deposits, examples include Goro and Acoje, (Philippines) and Ravensthorpe, Western Australia.

Volcanic-related deposits

* Volcanic hosted massive sulfide (VHMS) Cu-Pb-Zn including;

o Examples include Teutonic Bore and Golden Grove, Western Australia

+ Besshi type

+ Kuroko type

Metamorphically reworked deposits

* Podiform serpentinite-hosted paramagmatic iron oxide-chromite deposits, typified by Savage River, Tasmania iron ore, Coobina chromite deposit

* Broken Hill Type Pb-Zn-Ag, considered to be a class of reworked SEDEX deposits

Carbonatite - alkaline igneous related

* Phosphorus-tantalite-vermiculite (Phalaborwa South Africa)

* Rare earth elements - Mount Weld, Australia and Bayan Obo, Mongolia

* Diatreme hosted diamond in kimberlite, lamproite or lamprophyre

Sedimentary deposits

* Banded iron formation iron ore deposits, including

o Channel-iron deposits or pisolite type iron ore

* Heavy mineral sands ore deposits and other sand dune hosted deposits

* Alluvial gold, diamond, tin, platinum or black sand deposits

* Alluvial oxide zinc deposit type: sole example Skorpion Zinc

Sedimentary hydrothermal deposits

* SEDEX

o Lead-zinc-silver, typified by Red Dog, McArthur River, Mount Isa, etc

o Stratiform arkose-hosted and shale-hosted copper, typified by the Zambian copperbelt.

o Stratiform tungsten, typified by the Erzgebirge deposits, Czechoslovakia

o Exhalative spilite-chert hosted gold deposits

* Mississippi valley type (MVT) zinc-lead deposits

* Hematite iron ore deposits of altered banded iron formation

Astrobleme-related ores

*

o Sudbury Basin nickel and copper, Ontario, Canada

Extraction

The basic extraction of ore deposits follows the steps below;

1. Prospecting or Exploration to find and then define the extent and value of ore where it is located ("ore body")

2. Conduct resource estimation to mathematically estimate the size and grade of the deposit

3. Conduct a pre-feasibility study to determine the theoretical economics of the ore deposit. This identifies, early on, whether further investment in estimation and engineering studies is warranted and identifies key risks and areas for further work.

4. Conduct a feasibility study to evaluate the financial viability, technical and financial risks and robustness of the project and make a decision as whether to develop or walk away from a proposed mine project. This includes mine planning to evaluate the economically recoverable portion of the deposit, the metallurgy and ore recoverability, marketability and payability of the ore concentrates, engineering, milling and infrastructure costs, finance and equity requirements and a cradle to grave analysis of the possible mine, from the initial excavation all the way through to reclamation.

5. Development to create access to an ore body and building of mine plant and equipment

6. The operation of the mine in an active sense

7. Reclamation to make land where a mine had been suitable for future use

Trade

Ores (metals) are traded internationally and comprise a sizeable portion of international trade in raw materials both in value and volume. This is because the worldwide distribution of ores is unequal and dislocated from locations of peak demand and from smelting infrastructure.

Most base metals (copper, lead, zinc, nickel) are traded internationally on the London Metal Exchange, with smaller stockpiles and metals exchanges monitored by the COMEX and NYMEX exchanges in the United States and the Shanghai Futures Exchange in China.

Iron ore is traded between customer and producer, though various benchmark prices are set yearly between the major mining conglomerates and the major consumers, and this sets the stage for smaller participants.

Other, lesser, commodities do not have international clearing houses and benchmark prices, with most prices negotiated between suppliers and customers one-on-one. This generally makes determining the price of ores of this nature opaque and difficult. Such metals include lithium, niobium-tantalum, bismuth, antimony and rare earths. Most of these commodities are also dominated by one or two major suppliers with >60% of the world's reserves. The London Metal Exchange aims to add uranium to its list of metals on warrant.

The World Bank reports that China was the top importer of ores and metals in 2005 followed by the USA and Japan.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 6:55 AM 0 comments

Sunday, May 17, 2009

Mining engineering

Mining engineering is an engineering discipline that involves the practice, the theory, the science, the technology, and application of extracting and processing minerals from a naturally occurring environment. Mining engineering also includes processing minerals for additional value.

The need for mineral extraction and production is an essential activity of modern society. Mining activities by their nature cause a disturbance of the environment in and around which the minerals are located. Modern mining engineers must therefore be concerned not only with the production and processing of mineral commodities, but also with the mitigation of damage or to the environment as a result of that production and processing.

History of Mining Engineering

Since the beginning of civilization people have used stone, ceramics and, later, metals found on or close to the Earth's surface. These were used to manufacture early tools and weapons. For example, high quality flint found in northern France and southern England were used to set fire and break rock. Flint mines have been found in chalk areas where seams of the stone were followed underground by shafts and galleries. The oldest known mine on archaeological record is the "Lion Cave" in Swaziland. At this site, which by radiocarbon dating proves the mine to be about 43,000 years old, paleolithic humans mined mineral hematite, which contained iron and was ground to produce the red pigment ochre.

The ancient Romans were innovators of mining engineering. They developed large scale mining methods, especially the use of large volumes of water brought to the minehead by numerous aqueducts for hydraulic mining. The exposed rock was then attacked by fire-setting where fires were used to heat the rock, which would be quenched with a stream of water. The thermal shock cracked the rock, enabling it to be removed. In some mines the Romans utilized water-powered machinery such as reverse overshot water-wheels. These were used extensively in the copper mines at Rio Tinto in Spain, where one sequence comprised 16 such wheels arranged in pairs, and lifting water about 80 feet (24 m).

Black powder was first used in mining in Banská Štiavnica, Kingdom of Hungary present-day Slovakia in 1627. This allowed blasting of rock and earth to loosen and reveal ore veins, which was much faster than fire setting. The Industrial Revolution saw further advances in mining technologies, including improved explosives and steam-powered pumps, lifts and drills.

Mineral Exploration

Mining engineers are consulted for virtually every stage of a mining operation. The first role of engineering in mines is the discovery of a mineral deposit and the determination of the profitability of a mine.

Mineral discovery

Mining engineers are involved in the mineral discovery stage by working with geologists to identify a mineral reserve. The first step in discovering an ore body is to determine what minerals to test for. The geologists and engineers drill core samples and conduct surface surveys searching for specific compounds and ores. For example a mining engineer and geologist may target metallic ores such as galena for lead or chalcolite for copper. A mining engineer may also search for a non-metal such as phosphate, quartz, or coal.

The discovery can be made from research of mineral maps, academic geological reports or local, state, and national geological reports. Other sources of information include property assays, well drilling logs, and local word of mouth. Mineral research may also include satellite and airborne photographs. Unless the mineral exploration is done on public property, the owners of the property may play a significant role in the exploration process, and may be the original discoverer of the mineral deposit.

Mineral determination

After a prospective mineral is located, the mining engineer then determines the ore properties. This may involve chemical analysis of the ore to determine the composition of the sample. Once the mineral properties are identified, the next step is determining the quantity of the ore. This involves determining the extent of the deposit as well as the purity of the ore. The engineer drills additional core samples to find the limits of the deposit or seam and calculates the quantity of valuable material present in the deposit.

Feasibility study

Once the mineral identification and reserve amount is reasonably determined, the next step is to determine the feasibility of recovering the mineral deposit. A preliminary study shortly after the discovery of the deposit examines the market conditions such as the supply and demand of the mineral, the amount of ore needed to be moved to recover a certain quantity of that mineral as well as analysis of the cost associated with the operation. This pre-feasibility study determines whether the mining project is likely to be profitible; if it is then a more in-depth analysis of the deposit is undertaken. After the full extent of the ore body is known and has been examined by engineers, the feasibility study examines the cost of initial capital investment, methods of extraction, the cost of operation, an estimated length of time to payback, the gross revenue and net profit margin, any possible resale price of the land, the total life of the reserve, the total value of the reserve, investment in future projects, and the property owner or owners' contract. In addition, environmental impact, reclamation, possible legal ramifications and all government permitting are considered. These steps of analysis determine whether the mine company should proceed with the extraction of the minerals or whether the project should be abandoned. The mining company may decide to sell the rights to the reserve to a third party rather than develop it themselves, or the decision to proceed with extraction may be postponed indefinitely until market conditions become favorable.

Mining Operation

Mining engineers working in an established mine may work as an engineer for operations improvement, further mineral exploration, and operation capitalization by determining where in the mine to add equipment and personnel. The engineer may also work in supervision and management, or as an equipment and mineral salesperson. In addition to engineering and operations, the mining engineer may work as an environmental, health and safety manager or engineer.

Blasting

Explosives are used to break up a rock formation and aid in the collection of ore in a process called blasting. There are two types of explosives that can be used in mining: high velocity and low velocity. High velocity blasting uses high explosives while low velocity blasting is done with low explosives. Engineers determine the placement of the explosive charges and the blast sequence to efficiently and safely loosen the maximum amount of ore. They also are responsible for the safety of the miners by determining how best to support the rock ceiling in the newly-formed cave.

Reclamation

A mining engineer may be involved at the end of the mine life cycle when reclamation operations are planned and carried out. They also decide how to close a mine that has ceased operations to keep the public safe.

From http://en.wikipedia.org/

Labels: Outline of mining

Posted by my blog at 4:19 AM 0 comments

Mineral exploration

Mineral exploration is the process undertaken by companies, partnerships or corporations in the endeavour of finding ore (commercially viable concentrations of minerals) to mine. Mineral exploration is a much more intensive, organised and professional form of mineral prospecting and, though it frequently uses the services of prospecting, the process of mineral exploration on the whole is much more involved.

Stages of mineral exploration

* Area selection

* Target definition or generation

* Resource evaluation

* Reserve definition

* Extraction

Area selection

Area selection is a crucial step in professional mineral exploration. Selection of the best, most prospective, area in a mineral field, geological region or terrain will assist in making it not only possible to find ore deposits, but to find them easily, cheaply and quickly.

Area selection is based on applying the theories behind ore genesis, the knowledge of known ore occurrences and the method of their formation, to known geological regions via the study of geological maps, to determine potential areas where the particular class of ore deposit being sought may exist. Oftentimes new styles of deposits may be found which reveal opportunities to find look-alike deposit styles in rocks and terranes previously though unprospective, which may result in a process of pegging of leases in similar geological settings based on this new model or methodology. This behaviour is particularly well exemplified by exploration for Olympic Dam style deposits, particularly in South Australia and worldwide based on models of IOCG formation, which results in all coincident gravity and magnetic anomalies in appropriate settings being pegged for exploration.

This process applies the disciplines of basin modeling, structural geology, geochronology, petrology and a host of geophysical and geochemical disciplines to make predictions and draw parallels between the known ore deposits and their physical form and the unknown potential of finding a 'lookalike' within the area selected.

Area selection is also influenced by the commodity being sought; exploring for gold occurs in a different manner and within different rocks and areas to exploration for oil or natural gas or iron ore. Areas which are prospective for gold may not be prospective for other metals and commodities.